In which we discuss the simplest way to murder a Commodore 64

The first Commodore VIC-20s used a simple two prong power supply which delivered 9V AC to the machine. All it was essentially was a transformer: the rectifier to convert to DC was internal to the machine. It was simple and reliable.

When the C64 launched it used a very different power supply. A large and heavy box was connected to the machine by a DIN connector. This connector delivered both 9V AC and regulated 5V DC to the machine. As I understand it the 5V DC here powers the chips on the mainboard and the 9V does various things. Most importantly the 60Hz AC frequency is used as the system clock, but the signal is also rectified and regulated to provide voltage to the tape and user ports, amongst other things. The advantages of moving most of the work out to the external PSU was that it removed a heat source from inside the case. The real reason however was that this was a cheaper way of doing things. VIC-20’s from 1983 onwards used the same power architecture as the C64.

The problem is that these power supplies were, frankly, crap. The power brick would run very hot and was prone to failure. What’s worse is the way they tended to fail: when they were failing the DC voltage they were pumping out would slowly rise, and once it hit around 6V it would fry the chips inside the machine. This is how C64 power supplies got their reputation as machine killers. It’s a brave man who uses one of these today: I would venture to suggest that reliability is not improved by the application of 30-40 years of time. The prudent C64 user therefore either installs some sort of overvoltage protection, either internally or externally, or replaces the ageing supply with a modern supply.

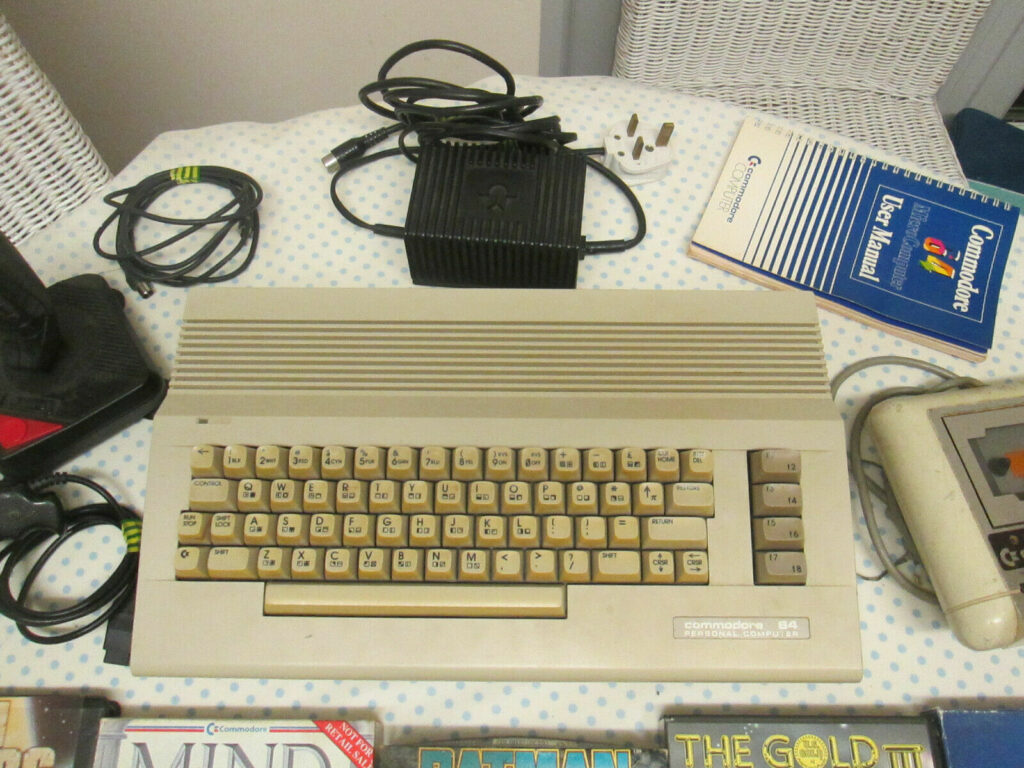

C64s were made all over the world in huge numbers over a long period of time and so you see great variation in components from one machine to the next. The supply for my childhood machine was the European wedge-shaped design, and I remember it being very hot and heavy. The supply I have here is an earlier, but I believe the most common, model of C64 power supply. It’s ridged and black with an embossed Commodore logo. It is also very heavy.

In the spirit of investigation I crack the PSU open and take a look inside. This is difficult to do without causing some damage but I don’t plan to every use this supply again so I’m not too concerned.

I knew what I was going to find but it’s still surprising to see it. I did always wonder as a child why the C64 power brick was so heavy compared to my Amiga and this is the reason why. Once they assembled them in the factory they filled the whole casing with epoxy. This seems pretty crazy to me: the idea is to help dissipate the heat from the components, but I can’t imagine it helps much. What it also does is make the supply completely unmaintainable. Forget doing a service job on one of these. We need a new supply.

Like this! Here’s a modern C64 PSU I bought on eBay. There’s a small cottage industry for things like this. This is a big upgrade: it’s lighter, runs much cooler and produces a nice, stable output. That’s the first step ticked off.